Product Description

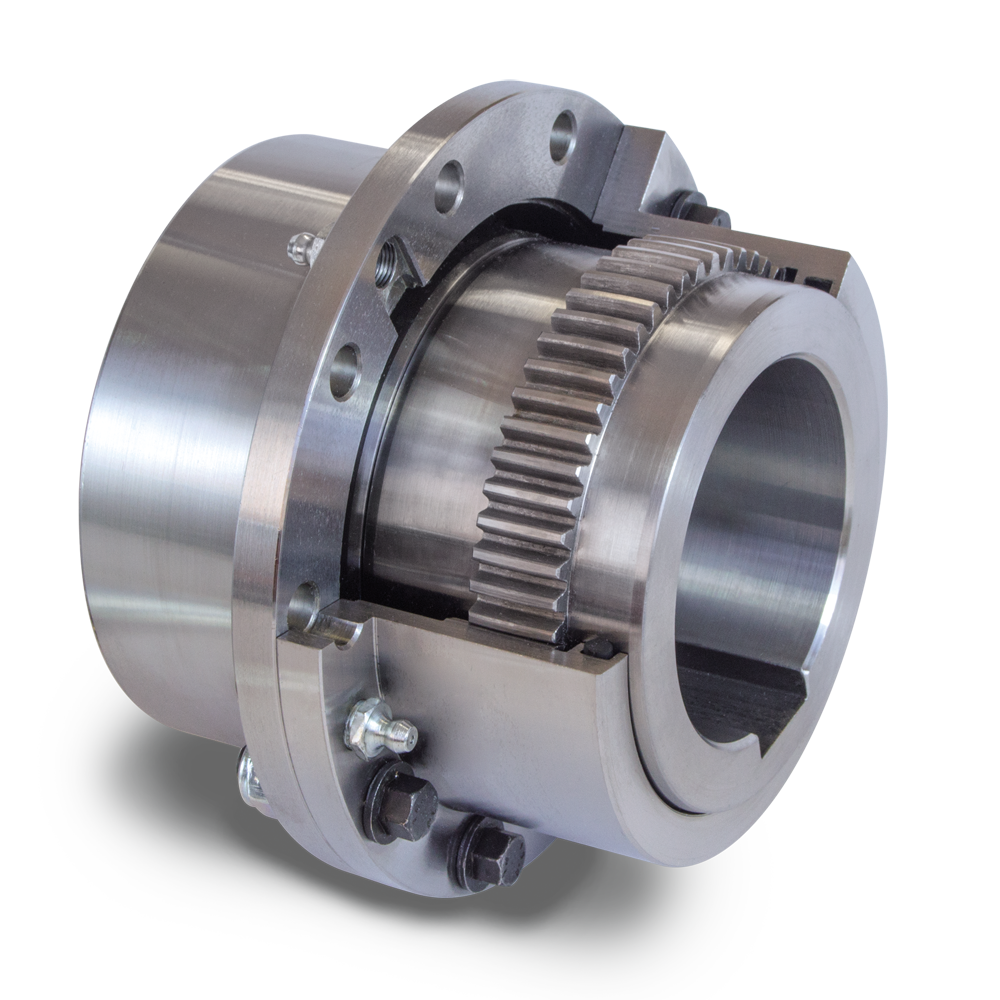

| Product Name | Curved Teeth Gear Coupling with Internal Teeth Nylon Sleeve |

| Material | Stainless Steel/Cast Iron Gear,Nylon Sleeve |

| Model NO. | MGF14-MGF125 |

| Bore Type | Finished Bore,Pilot Bore,Taper Bore |

| Manufacturing Process | CNC Maching |

| Weight | 0.2-10kg |

| Bore Diameter | 40-270mm |

Product Characteristics

– Double-Section tpye curved-tooth gear couping

– Widely applicable in various mechanical & hydraulic felds

– Nylon & steel matched, maintenance free

– Able to offset axial, radial & angular misalignments

– Axial plugging assembly, very convenient

Nylon Toothed Sleeve Characteristics

– Excellent Mechanical Performance

– High rigidity

– High temperature resistance (+100C)

– Not embrittled at low temperature

– Good slippery & frictional behaviour

– Excellent electrical insulation behaviour

– Chemical corrosion endurable

– HIgh Accuracy of processing

Salient features

* Simple construction-quick easy installation-No special tools required.

* Flexible insert caters for incident angular, parallel and axial misalignment.

* Absorbs shock loads and damps small amplitude vibration.

* Insert design presets correct distance between hubs, using raised pads on each leg of the insert.

* Available in a range of stock bore sizes. Can also be supplied with finished bore & keyway.

* Unaffected by moisture, grease and oils-including

non-aromatic and non-ketone solvents and temperatures within the range 40C to + 100C.

* Spacer coupling with spacer size depending upon the distance between two shaft ends.

Applications

Conveyor: Belt conveyor.AFC conveyor.Chain conveyor.Screw conveyor.

Pump: Water pump, oil pump, slush pump,etc

Fan: Draft fan,fanner, boiler fan,etc

Excavator: Bucket excavator. Bucket wheel excavators.Bucket wheel stacker reclaimer.

Crane: Tower crane.Gantry crane.Bridge crane.

Others: Various elevators.Coal plough.Ball mill.Crusher.Recreation machine.Blender

equipment.Centrifuger.Washer.Leather-making machine.machine for recreation park

mixer wire drawing machine.Extruder,dregs crusher of boiler. Plastic feeder.Rubber

smelling machine.etc.

Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

| Packing&Shipping | |

| Packing | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate. |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

About MIGHTY

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Tooth Couplings with Gear and Jaw Couplings

Tooth couplings, gear couplings, and jaw couplings are all types of couplings used in mechanical systems. Here’s a comparison of tooth couplings with gear and jaw couplings:

Tooth Couplings:

- They have interlocking teeth that provide high torque transmission capacity.

- Offer excellent misalignment compensation due to the tooth design.

- Can handle angular, radial, and axial misalignment.

- Transmit torque with low backlash and high torsional stiffness.

Gear Couplings:

- Use gears to transmit torque, providing high torque capacity.

- Handle angular misalignment but are less effective with radial and axial misalignment.

- Have backlash due to the gear design, which can affect precision applications.

- Require periodic lubrication and maintenance.

Jaw Couplings:

- Use elastomeric elements (jaws) for torque transmission.

- Provide good torsional stiffness and misalignment compensation.

- Handle moderate angular and axial misalignment but limited radial misalignment.

- Are simple in design and easy to install.

Ultimately, the choice between these couplings depends on the specific requirements of the application. Tooth couplings are preferred for high torque, precision, and demanding applications that require precise torque transmission and efficient misalignment compensation. Gear couplings excel in high torque situations but may have more backlash. Jaw couplings are suitable for simpler applications with moderate misalignment and torque requirements.

Suitability of Tooth Couplings for High-Speed Rotation and Heavy Loads

Yes, tooth couplings are well-suited for applications that involve high-speed rotation and heavy loads. Here’s why:

High-Speed Rotation: Tooth couplings are designed to transmit torque efficiently even at high rotational speeds. The tooth engagement provides a reliable means of torque transmission without slippage, making them ideal for high-speed applications.

Heavy Loads: Tooth couplings are robust and capable of handling substantial loads due to the interlocking teeth design. The teeth provide a secure connection that can transmit high levels of torque without deformation or damage.

Accuracy and Precision: Tooth couplings offer precise and accurate torque transmission, making them suitable for applications where precise positioning or synchronization is essential.

Minimal Backlash: Tooth couplings generally have minimal backlash due to the tight meshing of teeth. This reduces the play between the connected shafts, ensuring consistent motion and accurate positioning.

Sturdiness: Tooth couplings are manufactured from durable materials, making them capable of withstanding the stresses and forces associated with heavy loads and high speeds.

Customization: Tooth couplings can be tailored to specific applications by adjusting parameters such as tooth profile, size, and materials. This allows engineers to optimize the coupling’s performance for the intended use.

Advanced Designs: Modern tooth coupling designs incorporate advanced engineering techniques, such as finite element analysis, to ensure optimal performance even under challenging conditions.

Overall, tooth couplings offer a reliable solution for applications that demand both high-speed rotation and the ability to handle heavy loads effectively.

Benefits and Applications of Tooth Couplings

Using a tooth coupling offers several key benefits in mechanical systems:

- High Torque Transmission: Tooth couplings can handle high torque loads, making them suitable for heavy-duty applications.

- Angular Misalignment: They accommodate angular misalignment between shafts, reducing stress and wear on components.

- Axial Movement: Tooth couplings allow limited axial movement, which is crucial in applications with varying distances between shafts.

- Compact Design: Tooth couplings have a compact design, making them ideal for applications with limited space.

- Efficient Power Transmission: The meshing teeth provide efficient torque transmission with minimal backlash.

Tooth couplings find applications in various industries:

- Manufacturing: Used in conveyor systems, pumps, compressors, and machine tools.

- Automotive: Used in drivetrains, power transmission, and steering systems.

- Marine: Used in marine propulsion systems, winches, and deck machinery.

- Power Generation: Used in turbines, generators, and cooling tower fans.

- Aerospace: Used in aircraft control systems, landing gear, and engine accessories.

editor by CX 2024-03-14

by

Tags:

Leave a Reply