Product Description

DN100 EN877 SS316 RAPID S COUPLING ROUND NUT NO TEETH

Product details

Product Description

The steel couplings conform to all the mechanical requirement of DIN EN877/BS EN877. These couplings are composed of SS304 or SS 316 stainless steel shield, clamp assembly and EPDM(An elastomeric sealing sleeve that conform to the requirement of BS EN 681-1 and it also can resist the normal domestic effluents with thermal effects up to 70°C temperature). This elastomeric material was made by well balanced formula with the combination of outstanding properties in resisting abrasion, oil, grease, chemicals, ultraviolet, heat and cold conditions. This elastomeric sleeve also provides a cushioning element in the coupling to avoid shock, vibration and ensure a noiseless drainage system.

The stainless steel was selected for the clamp and shield assemblies because it possesses high corrosion resistance characteristics.

Our EN877 stainless steel coupling and grip collar are all produced using robots and fully automatic machinery. Not only do we have high production efficiency, but the quality of our products is very stable and reliable. It has been exported to many countries, such as Europe, Southeast Asia, Russia, etc.

The standard that our products comply with:

1) DIN EN877; BS EN877;

2) EN 681-1:1996+A3:2005

Product Model

| size | pcs/box | box size(cm) | kg/box | material | material | material | |||||||

| inch | mm | strip | bolt&nut | gasket | strip | bolt&nut | gasket | strip | bolt&nut | gasket | |||

| 1.5″ | DN40 | 100 | 42*32*25 | 12 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 2″ | DN50 | 100 | 42*32*25 | 12 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 2.5″ | DN70 | 100 | 50*37*25 | 16.5 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 3″ | DN75 | 100 | 57*42*27 | 17 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 4″ | DN100 | 50 | 58*39*27 | 13 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 5″ | DN125 | 50 | 67*47*31 | 15.5 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 6″ | DN150 | 50 | 54*38*60 | 20 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 8″ | DN200 | 20 | 63*51*33 | 11 | SS304 | SS304 | EPDM | SS316 | SS316 | EPDM | SS316 | SS304 | EPDM |

| 10″ | DN250 | ||||||||||||

| 12″ | DN300 | ||||||||||||

Packaging and Delivery:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

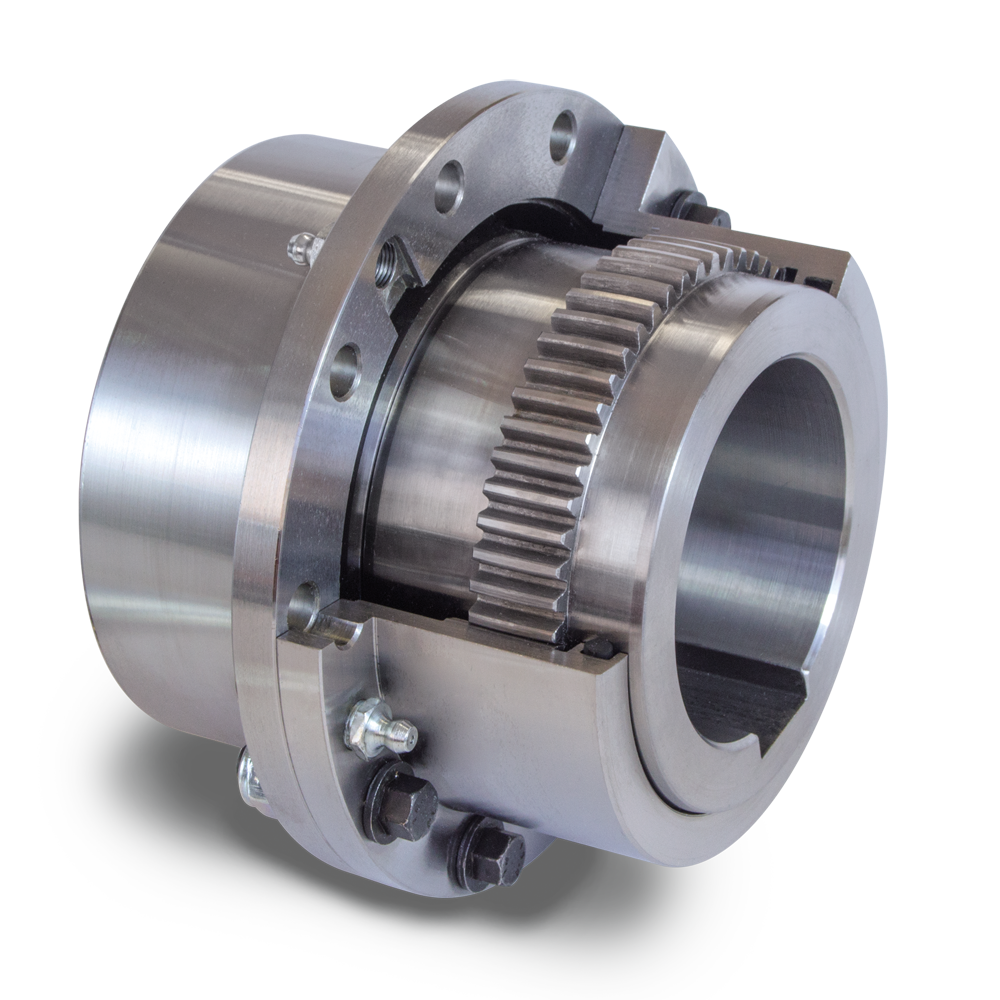

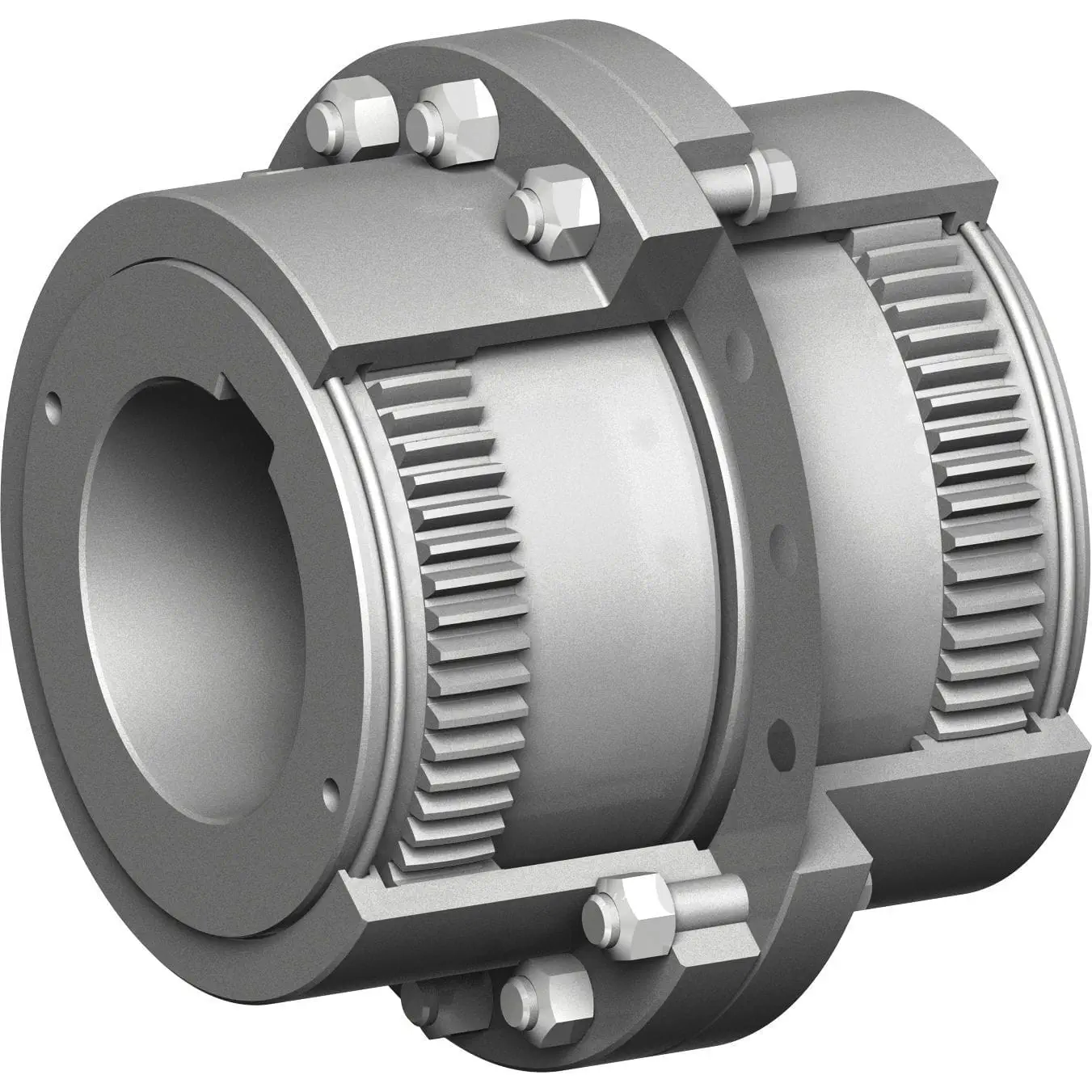

Comparison of Tooth Couplings with Gear and Jaw Couplings

Tooth couplings, gear couplings, and jaw couplings are all types of couplings used in mechanical systems. Here’s a comparison of tooth couplings with gear and jaw couplings:

Tooth Couplings:

- They have interlocking teeth that provide high torque transmission capacity.

- Offer excellent misalignment compensation due to the tooth design.

- Can handle angular, radial, and axial misalignment.

- Transmit torque with low backlash and high torsional stiffness.

Gear Couplings:

- Use gears to transmit torque, providing high torque capacity.

- Handle angular misalignment but are less effective with radial and axial misalignment.

- Have backlash due to the gear design, which can affect precision applications.

- Require periodic lubrication and maintenance.

Jaw Couplings:

- Use elastomeric elements (jaws) for torque transmission.

- Provide good torsional stiffness and misalignment compensation.

- Handle moderate angular and axial misalignment but limited radial misalignment.

- Are simple in design and easy to install.

Ultimately, the choice between these couplings depends on the specific requirements of the application. Tooth couplings are preferred for high torque, precision, and demanding applications that require precise torque transmission and efficient misalignment compensation. Gear couplings excel in high torque situations but may have more backlash. Jaw couplings are suitable for simpler applications with moderate misalignment and torque requirements.

Suitability of Tooth Couplings for High-Speed Rotation and Heavy Loads

Yes, tooth couplings are well-suited for applications that involve high-speed rotation and heavy loads. Here’s why:

High-Speed Rotation: Tooth couplings are designed to transmit torque efficiently even at high rotational speeds. The tooth engagement provides a reliable means of torque transmission without slippage, making them ideal for high-speed applications.

Heavy Loads: Tooth couplings are robust and capable of handling substantial loads due to the interlocking teeth design. The teeth provide a secure connection that can transmit high levels of torque without deformation or damage.

Accuracy and Precision: Tooth couplings offer precise and accurate torque transmission, making them suitable for applications where precise positioning or synchronization is essential.

Minimal Backlash: Tooth couplings generally have minimal backlash due to the tight meshing of teeth. This reduces the play between the connected shafts, ensuring consistent motion and accurate positioning.

Sturdiness: Tooth couplings are manufactured from durable materials, making them capable of withstanding the stresses and forces associated with heavy loads and high speeds.

Customization: Tooth couplings can be tailored to specific applications by adjusting parameters such as tooth profile, size, and materials. This allows engineers to optimize the coupling’s performance for the intended use.

Advanced Designs: Modern tooth coupling designs incorporate advanced engineering techniques, such as finite element analysis, to ensure optimal performance even under challenging conditions.

Overall, tooth couplings offer a reliable solution for applications that demand both high-speed rotation and the ability to handle heavy loads effectively.

Proper Installation and Maintenance of Tooth Couplings

To ensure the proper function and longevity of a tooth coupling, follow these guidelines:

Installation:

- Ensure shafts are aligned within manufacturer specifications to prevent excessive loads on the coupling.

- Clean and inspect the coupling components before installation to avoid debris or contaminants.

- Use appropriate tools and methods to achieve proper fit between the coupling and the shafts.

- Follow the manufacturer’s instructions for tightening bolts or fasteners to the recommended torque.

Maintenance:

- Regularly inspect the coupling for signs of wear, such as tooth damage, corrosion, or misalignment.

- Check for any abnormal vibrations, noise, or overheating during operation, which could indicate coupling issues.

- Keep the coupling and surrounding area clean to prevent the accumulation of dirt or debris.

- Regularly lubricate the coupling as per the manufacturer’s recommendations to reduce friction and wear.

- Monitor the alignment of the connected equipment and address any misalignment promptly.

- Replace worn or damaged components promptly to avoid further damage and maintain coupling performance.

Following proper installation and maintenance practices will help maximize the efficiency and service life of the tooth coupling.

editor by CX 2024-04-16

by

Tags:

Leave a Reply