Product Description

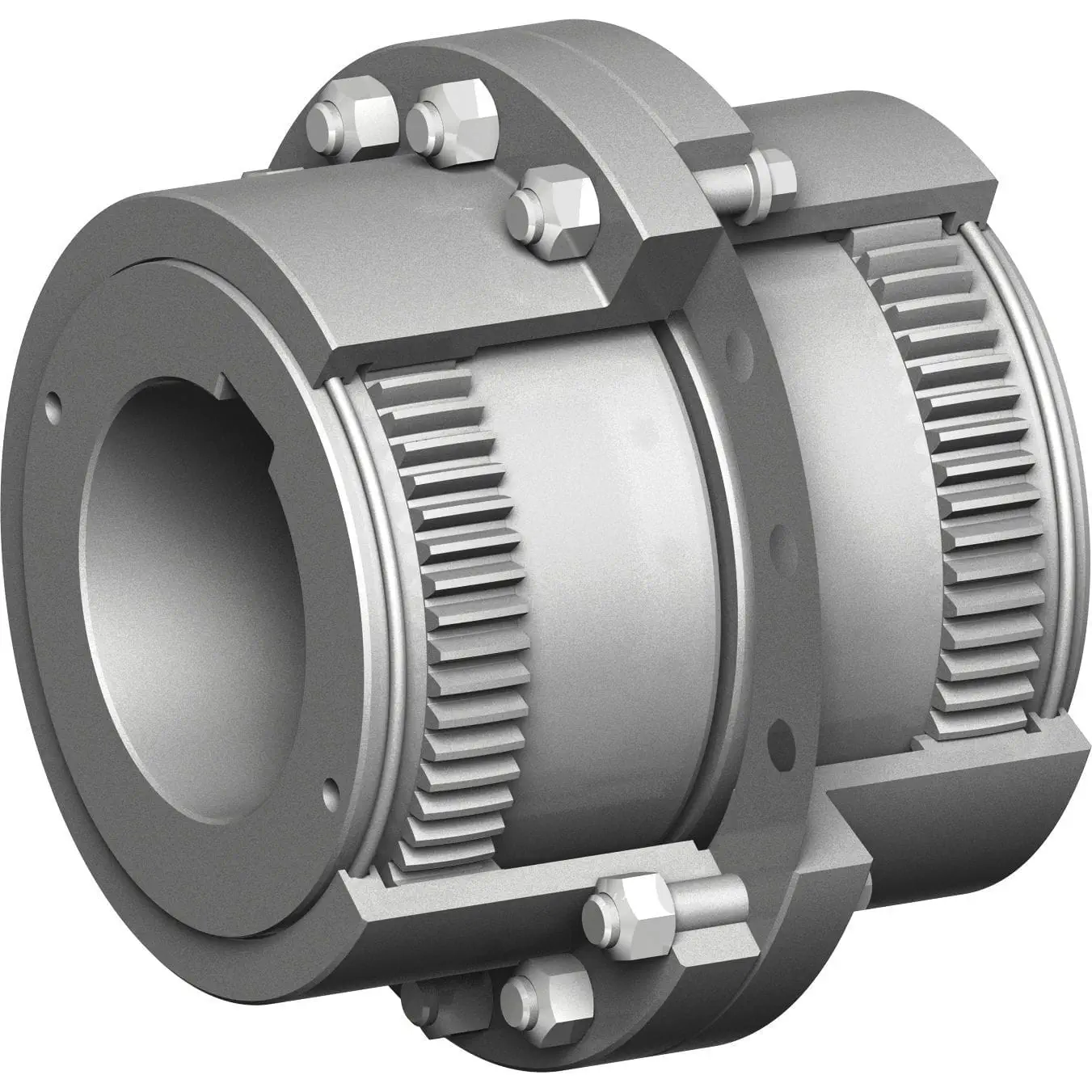

Densen customized drum toothed coupling gear tooth couplings,gear shaft coupling,flexible gear couplings

Product show

| Product Name | GIICL6 type stainless steel sleeve gear coupling,gear shaft coupling,sleeve gear coupling |

| DN mm | 16-1040mm |

| Rated Torque | 0.4~4500 kN·m |

| Allowalbe Speed | 4000~460RPM |

| Material | 45# Steel or 42CrMo |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Why Choose Us

1. One stop service:

We have 5 own factories and 50+ sub-contractors located in different areas of China to offer you one-stop manufacturing and purchasing services to help you save time and reduce procurement cost.

2. Your eyes in China:

Our commitment to quality permeates from quoting, scheduling, production, inspection to deliver into your warehouse, our QC team will remark the errors if has on QC documents for your checking before delivery as your 3rd party.

3. Your R&Dconsultant:

With professional engineers team and 29 years manufacture experience ,we would help you work out problems during new parts’ development, optimize design and recommend the most cost-effective solution.

4. Your Emergency Solver:

With continued grown factories team and our QC teams located in different areas, if customers need to expedite the delivery, we would be able to adopt another factory to produce together immediately.

5. Quality Guaranty:

No matter how long time the products delivered, we are responsible for the quality. In case the products be rejected, we would replace them or return fund according to your demand without hesitation

FAQQ1. Are you a manufacturer or a trader?

Manufacture, we have 5 own foundries, 4 in ZheJiang Province, 1 in ZHangZhoug Province

Q2. Do you have MOQ request?

1 pcs per order is ok with us , unless material is seldom used.

Q3. If I only have a sample,without drawings, can you quote then manufacture for me?

Just send us the sample, we would have the sample simulated and measured by professional equipment then issue formal drawings for

you , at the same time, we could help you optimize the design according to your demand and related processes’ feasibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Capability of Tooth Couplings to Handle Torque and Angular Displacement

Yes, tooth couplings are designed to withstand high levels of torque and angular displacement. These couplings are capable of transmitting significant amounts of torque between shafts while accommodating angular misalignment. The teeth on the coupling’s hubs engage with each other, providing a secure connection that can transmit torque efficiently.

Angular displacement, also known as misalignment, occurs when the connected shafts are not perfectly aligned. Tooth couplings can accommodate a certain degree of angular misalignment without compromising their performance. The design of the teeth allows for a degree of flexibility, which helps in compensating for minor misalignments that may occur due to various factors.

However, it’s important to note that tooth couplings have their limits in terms of torque capacity and misalignment compensation. Excessive torque beyond the coupling’s rated capacity or severe angular misalignment can lead to premature wear, damage, or even coupling failure. Engineers should carefully consider the coupling’s specifications, application requirements, and operating conditions to ensure proper performance and longevity.

Backlash in Tooth Couplings and Its Impact on Performance

Backlash is a crucial factor in tooth couplings that affects their performance. Backlash refers to the angular movement or play between the teeth of the coupling when there is a change in the direction of loading. It is the amount by which a tooth space exceeds the thickness of the engaged tooth.

The impact of backlash on performance includes:

- Positioning Accuracy: Backlash can lead to positioning inaccuracies in systems where precise motion control is required. As the direction of loading changes, the teeth need to engage before transmitting torque, causing a delay and affecting accuracy.

- Reversal Shock: In systems with frequent changes in direction, backlash can result in a sudden impact or shock when the teeth engage, leading to vibrations and potential damage to the coupling and connected components.

- System Response: Backlash can introduce a dead zone or delay in the system response when the loading direction changes. This can affect the system’s ability to respond quickly to changes in input.

- Reduced Efficiency: Backlash causes energy loss due to the need to overcome the play between teeth during direction changes. This can reduce the overall efficiency of the system.

- Wear and Fatigue: Backlash can lead to wear and fatigue of the coupling teeth and other components due to repeated impacts during loading changes.

- Noise and Vibration: The sudden engagement of teeth can generate noise and vibration, affecting the overall smoothness of operation and potentially leading to fatigue failure.

Minimizing backlash is important for improving the performance of tooth couplings. Some couplings are designed with features to reduce or compensate for backlash, while others require precise alignment and regular maintenance to manage backlash within acceptable limits.

Role of Tooth Couplings in Mechanical Systems

A tooth coupling is a type of mechanical coupling that connects two shafts to transmit torque while allowing for angular misalignment and axial movement between them. It consists of two hubs with external teeth that mesh together, engaging the teeth to transfer torque from one shaft to another. Tooth couplings are commonly used in various mechanical systems to provide a reliable and efficient means of transmitting power and motion.

editor by CX 2024-04-17

by

Tags:

Leave a Reply