Product Description

Key attributes

| Model NO. | GICL Type | Mounting | as Per Required |

| Body Material | Carbon Steel or as Required | Appearance Shape | Round |

| Delivery Time | 20-45 Days | Transport Package | Wooden Box |

| Specification | as your requirement | Trademark | Huading |

| Origin | China | HS Code | 8483600090 |

| Production Capacity | 100000 Pieces/ Year |

Product Description

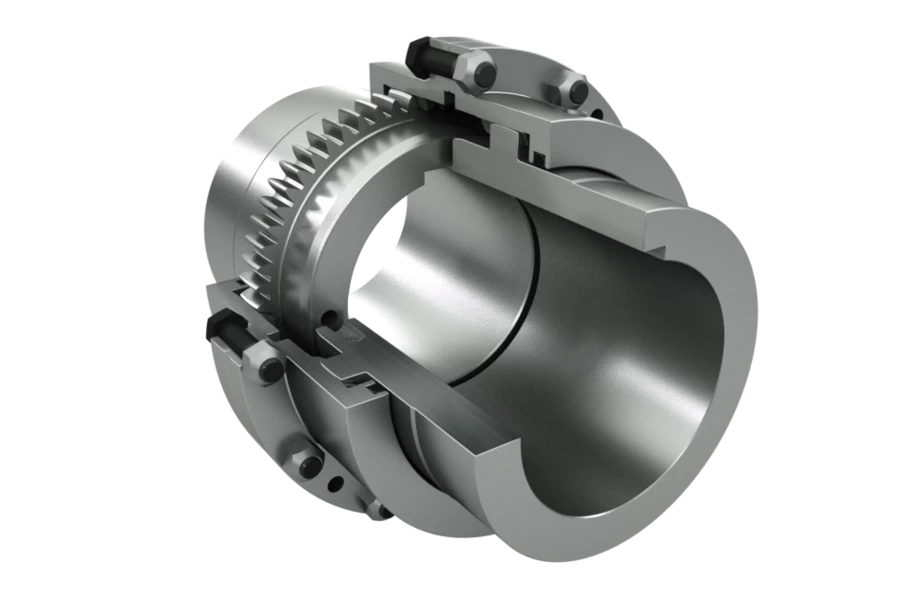

♦Description

1. Strong load-bearing capacity. When the outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling are the same, the load-bearing capacity of the drum tooth coupling is increased by an average of 15-20% compared to the straight tooth coupling;

2. The angular displacement compensation is large. When the radial displacement is zero,

The allowable angular displacement of the straight tooth coupling is 1o, while the allowable angular displacement of the drum tooth coupling is 1o30 ‘, an increase of 50%. Under the same modulus, number of teeth, and tooth width, the allowable angular displacement of drum teeth is greater than that of straight teeth;

3. The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoiding the drawbacks of edge compression and stress concentration of straight teeth under angular displacement. Simultaneously improving the friction and wear condition of the tooth surface, reducing noise, and having a long maintenance cycle;

4. The outer gear sleeve has a trumpet shaped tooth end, making it very convenient to install and remove the inner and outer teeth;

5. The transmission efficiency is as high as 99.7%;

Based on the above characteristics, drum tooth couplings have been widely used both domestically and internationally to replace straight tooth couplings.

♦Detailed Pictures

♦Basic Parameter and Main Dimension

♦Draft

Packaging & Shipping

Plywood case with bubble wrap

Other Products List

Company Profile

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in designing and manufacturing various types of coupling. It has a superior geographical location, located within the southern industrial park of HangZhou.There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals. Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode…

We are an integrated enterprise of industry and trade.The leading products of the company are mainly universal coupling, gear coupling, flexible pin gear coupling, flexible sleeve pin coupling, diaphragm coupling, star coupling, quincunx flexible coupling, tire coupling, roller chain coupling, flange coupling, and other thousands of specifications coupling, widely used in metallurgy, mining, lifting transport, petroleum chemical industry, papermaking, pharmaceutical, textile, printing and dyeing, ships, locomotives and equipment, longitudinal welded pipe cut, HangZhou, straightening and other sectors, it provides strong support of technology and equipment for the localization of imported domestic numerous couplings, won the praise of clients. Our products have been exported to the USA, UK, France, Italy, Russia, Dubai, Brazil, Saudi Arabia, Japan, Korea, Indonesia, Thailand, Philippines, Vietnam, Sri Lanka, Iran, and other countries.

Our company supplies different kinds of products: High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide products of good quality at a reasonable price.

♦Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing → Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

Certification

ISO 9001 ISO 14001 ISO 45001

1. Certificate number: SMS.W.II./141998/A.0

2. Certification Body: Bureau Veritas

3. Product: Shaft-Cardan shaft

FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2: Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3: How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples ? Is it free or extra ?

Yes, we could offer the sample but not for free. Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstance.

Q 6: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 7: Do you have inspection procedures for coupling ?

A: 100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A: T/T. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Tooth Couplings

There are industry standards and guidelines that govern the design and use of tooth couplings. Some of these include:

- AGMA 9002-A94: This standard provides information on the selection and application of flexible couplings, including tooth couplings.

- ISO 14691: This international standard specifies methods for calculating the load capacity of tooth couplings.

- DIN 740: This German standard provides information on dimensions and requirements for tooth couplings.

- API 671: This American Petroleum Institute (API) standard specifies requirements for special purpose couplings, including tooth couplings, for use in the petroleum and natural gas industries.

These standards provide guidelines for the design, selection, installation, and maintenance of tooth couplings to ensure safe and reliable operation. Engineers and designers often refer to these standards to ensure that tooth couplings are used appropriately in various applications.

Identifying Wear or Damage in Tooth Couplings

Wear or damage in a tooth coupling can lead to performance issues and potential failures. Here are some signs to watch for and methods to identify problems:

- Abnormal Noise: Unusual noise during operation, such as rattling, grinding, or clicking, can indicate misalignment or wear in the teeth.

- Increased Vibration: Excessive vibration may suggest misalignment, worn teeth, or other issues affecting coupling performance.

- Temperature Rise: If the coupling becomes unusually hot during operation, it could indicate friction due to misalignment or damaged teeth.

- Visual Inspection: Regularly inspect the coupling for signs of wear, corrosion, pitting, or chipped teeth. Use proper lighting and magnification if needed.

- Measurement: Check tooth clearances using specialized measurement tools to identify any significant deviations from specifications.

- Runout Measurement: Measure coupling runout to detect eccentricity or misalignment that could lead to premature wear.

- Alignment Check: Use laser alignment tools to ensure proper shaft alignment, preventing undue stress on the coupling teeth.

- Lubrication Analysis: Analyze the lubricant for metal particles or signs of contamination, which could result from wear and damage.

Regular inspection, monitoring operating conditions, and addressing any signs of wear or damage promptly can help extend the life of the tooth coupling and prevent unexpected failures.

Factors for Selecting a Tooth Coupling

When choosing a tooth coupling for a specific application, consider the following factors:

- Load and Torque: Determine the maximum load and torque requirements of the application to ensure the coupling can handle the expected forces.

- Speed: Consider the rotational speed of the equipment as higher speeds may require specialized couplings with enhanced balance and accuracy.

- Alignment Tolerance: Evaluate the degree of misalignment the coupling can accommodate without affecting performance.

- Environment: Assess the operating environment, including temperature, humidity, and exposure to contaminants or corrosive substances.

- Size and Space: Choose a coupling size that fits within the available space and meets the connection requirements of the shafts.

- Backlash: Determine the acceptable level of backlash, as some applications may require minimal or zero backlash for precise motion.

- Shock and Vibration: Consider whether the application involves frequent shocks or vibrations and choose a coupling that can dampen these effects.

- Material: Select the appropriate coupling material based on factors like corrosion resistance, strength, and compatibility with the connected components.

- Maintenance: Evaluate the ease of maintenance, including access to lubrication points and the need for periodic inspection and replacement.

- Cost: Balance the performance requirements with the budget constraints of the project.

Considering these factors will help you choose the right tooth coupling for your specific application, ensuring optimal performance and reliability.

editor by CX 2024-05-08

by

Tags:

Leave a Reply