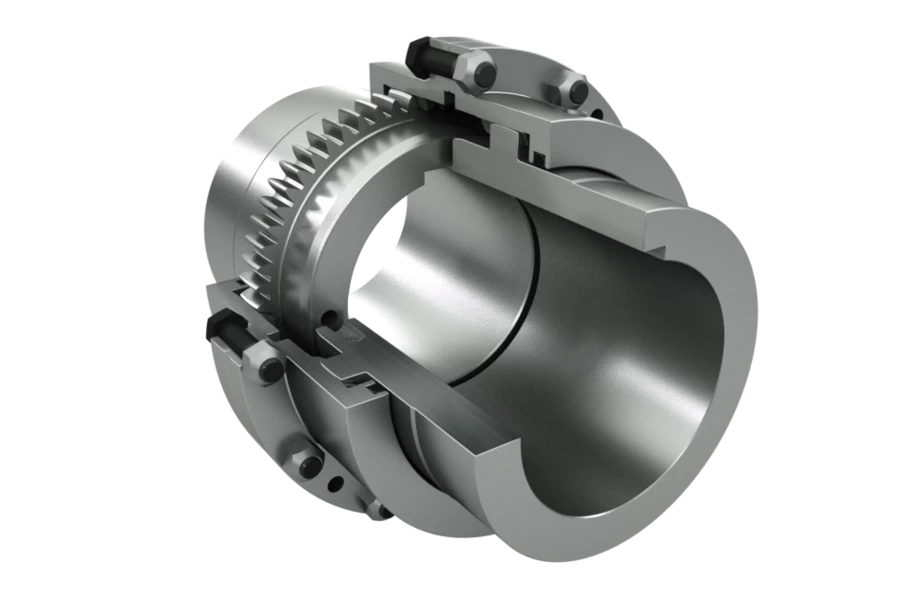

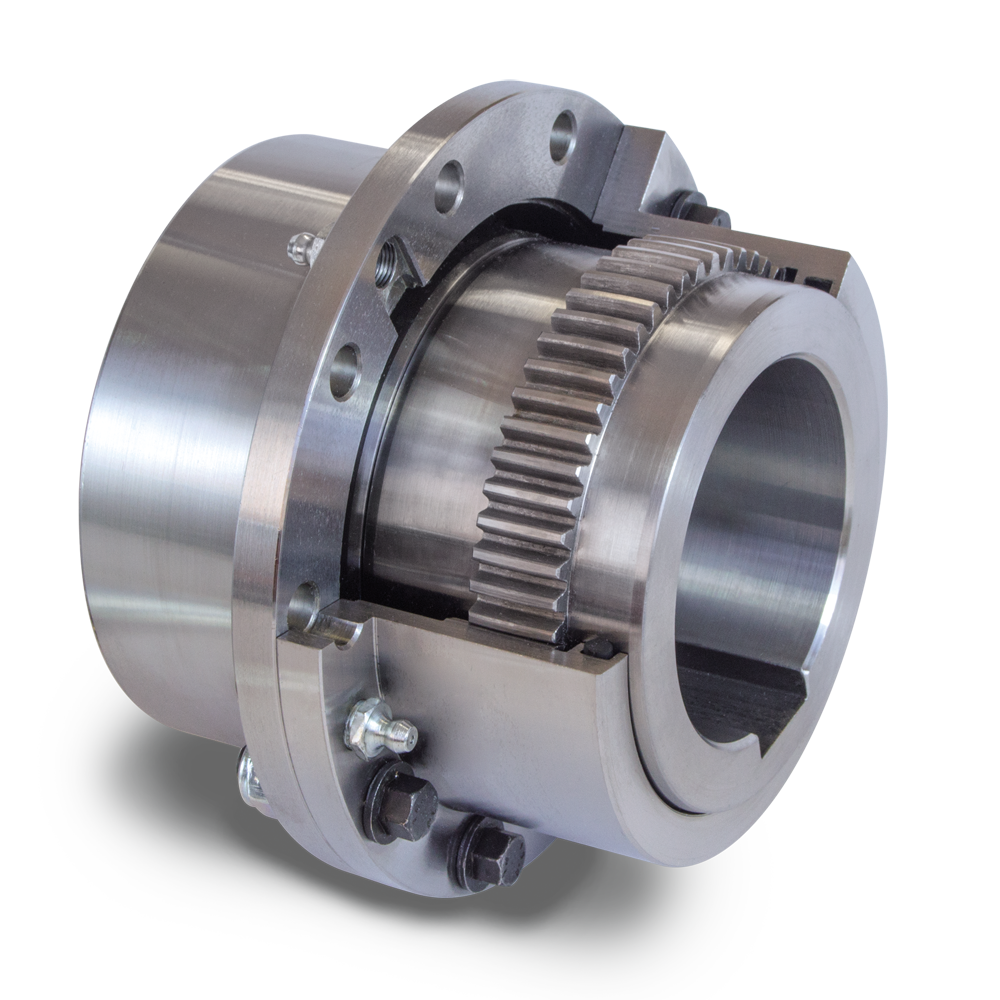

TOOTH COUPLING FOR BIOMASS PLANTS

The Importance of Tooth Coupling in Biomass Plants

Biomass plants rely on tooth couplings to ensure efficient power transmission between different components. These couplings play a crucial role in maintaining the integrity and reliability of the plant’s operations.

Understanding Tooth Coupling Design

The design of tooth couplings is based on a complex set of principles and considerations. Here are some key aspects to understand:

1. Tooth Profile Shape Optimization

The tooth profile shape of the coupling is optimized to maximize torque transmission while minimizing stress concentrations. This ensures efficient power transfer and reduces the risk of premature failure.

2. Material Selection

The choice of materials for tooth couplings is critical to their performance and longevity. High-strength alloys with excellent fatigue resistance and wear properties are commonly used to withstand the demanding operating conditions of biomass plants.

3. Misalignment Compensation

Tooth couplings are designed to compensate for misalignments that may occur between the connected shafts. This feature helps to minimize the transmission of undesirable vibrations and ensures smooth operation.

4. Lubrication System

Proper lubrication is essential for the smooth functioning of tooth couplings. A dedicated lubrication system is employed to reduce friction, dissipate heat, and prevent premature wear.

5. Overload Protection

Tooth couplings incorporate overload protection mechanisms to safeguard the connected machinery from excessive torque or shock loads. These features help prevent damage to the equipment and ensure uninterrupted operation.

Choosing and Customizing the Right Tooth Coupling

When selecting or customizing a tooth coupling for biomass plants, several parameters and practical considerations should be taken into account:

– Torque Capacity

The tooth coupling should be chosen based on the specific torque requirements of the application. It is essential to ensure that the coupling can handle the maximum torque without exceeding its designed limits.

– Shaft Misalignment Tolerance

Consider the expected misalignment between the connected shafts and select a tooth coupling that can accommodate the required tolerance levels. This ensures proper functionality and minimizes stress on the system.

– Operating Environment

Evaluate the operating conditions, such as temperature, humidity, and presence of contaminants, to determine the appropriate tooth coupling materials and protective coatings.

– Maintenance Requirements

Consider the ease of maintenance and accessibility of the tooth coupling for inspection, lubrication, and potential replacement. A well-designed coupling should facilitate routine maintenance tasks.

– Cost-Effectiveness

Balance the initial investment and long-term operational costs when selecting a tooth coupling. A reliable and durable coupling may initially cost more but can provide significant savings over its lifespan.

About HZPT

HZPT is a modern enterprise located in Hangzhou, Zhejiang Province. We specialize in research, development, production, and international trade of coupling products. Our core values revolve around integrity, unity, progress, and innovation.

With expertise in high-tech development, international trade, industrial investment, and global networks, we are committed to becoming a leading international group. Our product range includes drum couplings, pin & bush couplings, serpentine spring couplings, universal couplings, star couplings, expansion couplings, membrane couplings, tire couplings, and more.

We have a comprehensive and scientific quality management system with our own technology development and testing department. Our certifications include CQC, ISO, CE, among others. We are dedicated to providing excellent sales service and technical support to our customers.

With a customer-centric approach and a focus on collaboration and mutual development, we have established partnerships with over a hundred companies. We invite you to explore our wide range of tooth coupling products, each boasting the following advantages:

1. Superior Torque Transmission

Our tooth couplings are designed to maximize torque transmission, ensuring efficient power transfer and reliable operation in biomass plants.

2. Exceptional Durability

Constructed from high-strength alloys with excellent fatigue resistance and wear properties, our tooth couplings are built to withstand the demanding conditions of biomass plants, resulting in long service life.

3. Misalignment Compensation

Our tooth couplings effectively compensate for shaft misalignments, reducing vibrations and minimizing stress on the connected machinery, thus enhancing overall system performance.

4. Reliable Lubrication System

Equipped with a dedicated lubrication system, our tooth couplings ensure proper lubrication, heat dissipation, and reduced friction, resulting in smooth operation and extended coupling life.

5. Enhanced Overload Protection

Our tooth couplings incorporate robust overload protection mechanisms, safeguarding the connected machinery from excessive torque or shock loads, thus preventing potential damage and costly downtime.